The compact and newly overhauled or completely new insulated containers are outstandingly suitable for being used as drying kilns. The inside walls are made of stainless steel or aluminium and they as well as the robust base have good insulation properties. In the factory, they will be equipped with high-quality components like fans, heaters, spraying unit, exhaust fan and inlet flaps as well as climate- and wood moisture content measurement.

The control unit, the drying schedules and our experience as kiln producer make the simple containers excellent but low-budget drying kilns which we perfectly adapt to customer requirements.

- Uniform drying

- Cost-saving and economic

- Easy installation

- Very good insulation

- Easy control

- Solutions adapted to customer requirements

- Front- and track loading

Air Classic Drying Container KILN

| Technical Data | Type | TC6 | TC12 |

|---|---|---|---|

| Stackroom-Length | m | 5.55 | 11.60 |

| Stackroom-Width | m | 1.25 | 1.25 |

| Stackroom-Height | m | 2.00 | 2.20 |

| Stackroom gross capacity | m³ | 13.90 | 31.90 |

| Total length incl. track | m | 13.00 | 25.00 |

| El. power supply with E-Htg. | kW | 20.20 | 39.50 |

| El. average consumption with E-Htg. | kW | 11.3 | 22.5 |

| El. average consumption with E-Htg. and heat recovery | kW | 9.00 | 18.00 |

| El. power supply with HW-Htg. | kW | 4.20 | 7.50 |

| El. average consumption with HW-Htg. | kW | 2.50 | 4.50 |

| HW-Htg system power supply | kW | 25.00 | 50.00 |

| HW-Htg average consumption | kW | 12.50 | 25.00 |

Special dimensions between 6-18 metres are available to meet individual customer's needs.

The drying process

After loading the wood by means of track car, the drying process can be started. Laterally mounted fans press the air through hot water heaters or electruc heaters and evenly distribute the air over the entire kiln length. The drying climate can be exactly controlled due to air exchange by exhaust fan and air inlet flaps.

A counterflow heat exchanger can be used as an option. The fresh incoming air is heated quite effectively by the warm and humid exhaust air. This conventional drying kilns are characterised by fastness, equability and economy.

Standard sizes are:

- 6m container 6.1m x 2.4m x 2.6m (LxWxH)

- 12m container 12.2m x 2.4m x 2.9m (LxWxH)

- Special dimensions are possible at any time.

Operation

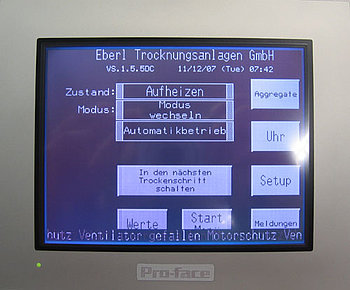

Simple, intuitive, quick

On our user-friendly touch panel, simply enter the wood type, wood thickness and the desired final moisture content.

After that, all you have to do is press the start button, and the kiln will take care of the rest by itself.

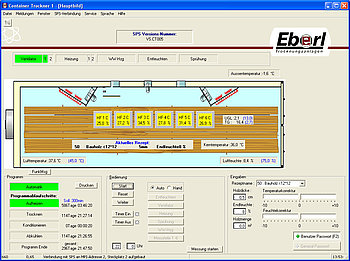

In order to facilitate your daily work with our kilns, we offer a visualisation program. With this you can comfortably monitor and control your kiln from your office computer. The simple interface allows you to enter all relevant data and settings as well as saving and printing logs or diagrams of the drying process. It is even possible to remotely control your kiln using your smartphone.

Container kiln brochure

You can find Detailed information in our container kiln brochure as PDF-Download.

Our practical inquiry form will lead you quickly to all answers.

Now for the form

eberl-trocknungsanlagen.de

eberl-trocknungsanlagen.de