Special features and advantages of the procedure:

- A saturated steam atmosphere can only be created in a tank. This

ensures exact temperature distribution and colouring. - The high steam temperature in overpressure shortens the colouring

process extremely. This saves a lot of time and energy. - The superheating and dehumidification of the steam atmosphere

enables controlled drying during the steaming process and thus

saves one work step. - Optimal thermal insulation saves a lot of energy at these high

temperatures.

Steam Drying Process

In the conventional steaming process, coniferous woods

require very long steaming times for obtaining the shade

of antique wood, three weeks as a rule. In addition to that,

specific and expensive heating systems are necessary for

steam production. After the steaming process, the wood

needs to be restacked and dried in a complex process.

The EBERL steam dryer was specifically developed for fast

and economic steaming and at the same time drying coniferous

wood. But also many types of hard wood obtain

really interesting colour shades.

Steam Dryer

| Technical specifications | Typ | 20/65 | 20/125 | 25/150 | 27/150 | 29/150 | 34/150 | 34/225 |

| Kiln diameter | m | 2 | 2 | 2,5 | 2,7 | 2,9 | 3,4 | 3,4 |

| Stack room length | m | 6,6 | 12,6 | 15,1 | 15,1 | 15,1 | 15,1 | 22,6 |

| Stack room width | m | 1,2 | 1,2 | 1,25 | 1,4 | 1,25 | 1,5 | 1,5 |

| Stack room height | m | 1,58 | 1,58 | 2,18 | 2,28 | 2,58 | 3,03 | 3,03 |

| Stack room gross capacity | m³ | 12,5 | 23,9 | 41,1 | 48,2 | 48,7 | 68,6 | 102,7 |

| Length of the kiln | m | 10 | 16 | 18,5 | 18,5 | 18,5 | 18,5 | 26 |

| Width of the kiln | m | 2,5 | 2,5 | 3 | 3,2 | 3,4 | 3,9 | 3,9 |

| Height of the kiln | m | 2,6 | 2,6 | 3,1 | 3,3 | 3,5 | 4 | 4 |

| Electrical power supply | kW | 24 | 45 | 81 | 88 | 96 | 117 | 168 |

| Average consumption | kW | 6 | 11 | 18 | 22 | 22 | 32 | 45 |

The machines are available in variable length (0.5 m increments) |

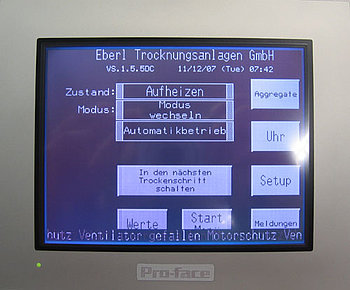

Operation

Simple, intuitive, quick

On our user-friendly touch panel, simply enter the wood type, wood thickness and the desired final moisture content.

After that, all you have to do is press the start button, and the kiln will take care of the rest by itself.

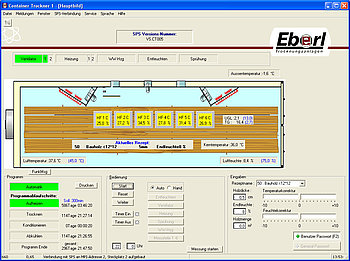

In order to facilitate your daily work with our kilns, we offer a visualisation program. With this you can comfortably monitor and control your kiln from your office computer. The simple interface allows you to enter all relevant data and settings as well as saving and printing logs or diagrams of the drying process. It is even possible to remotely control your kiln using your smartphone.

Steam Dryer brochure

You can find Detailed information in Steam Dryer Brochure as PDF-Download.

Our practical inquiry form will lead you quickly to all answers.

Now for the form

eberl-trocknungsanlagen.de

eberl-trocknungsanlagen.de